When motivation met manufacturing, masks became a reality.

Spectrum Health and area manufacturers joined forces to create personal protection equipment while supplies of traditional masks became scarce during the pandemic.

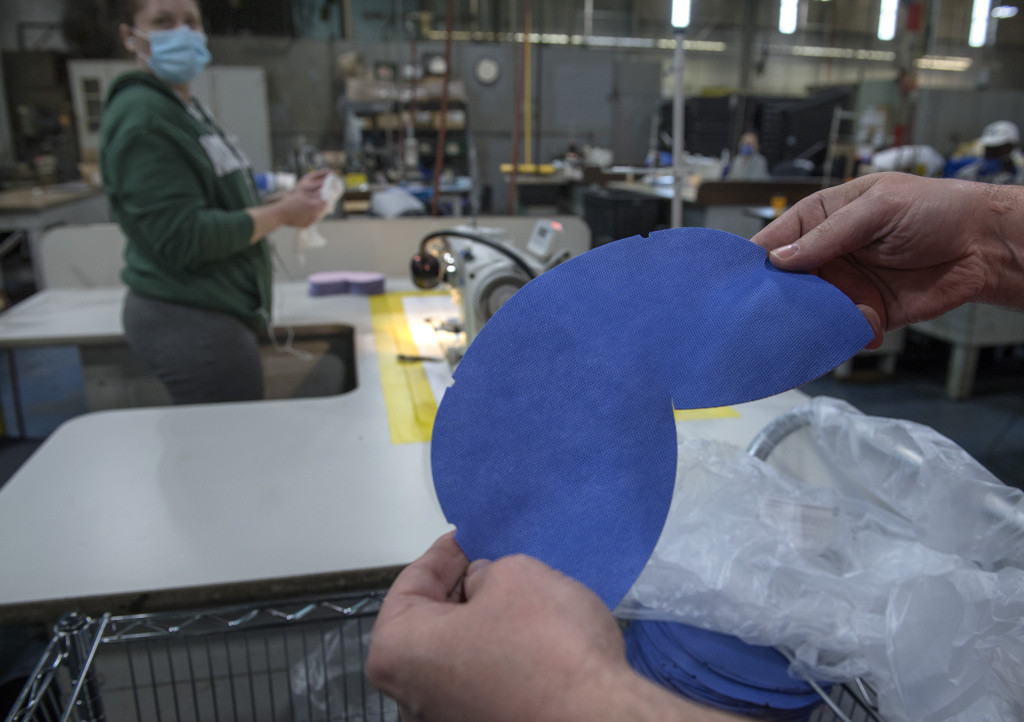

Companies created blue masks made from a high-filtration material typically used during surgeries. Now that the supply of traditional masks have reached a sustainable level, Spectrum Health plans to distribute the blue masks to non-patient-facing employees for their personal use.

The masks are crafted from the H-600 material used in operating rooms to keep surgical tools sterile. Tests showed the material filtered 98% of particles from the air. Because of surgery postponement during COVID-19 shutdowns, there was a surplus of the H-600 material.

“It proved to be a good filtering material we could sew into masks,” Travis Barkel, Spectrum Health Supply Chain manager, said. “We were searching for a way to make a mask that is effective, out of material that is abundant.”

Spectrum Health Value Analysis team members initially learned of the material’s 98% filtration effectiveness through University of Florida studies and collaborated with Bissell Incorporated and SGS Laboratories on further testing.

Spectrum Health team members worked with local furniture manufacturer Steelcase on mask design, then enlisted six area manufacturers—American Seating, Comfort Research, Fomcore, Genesis Seating, Irwin Seating and Ventura Manufacturing—for production of 100,000 blue masks.

Moving forward, patient-facing team members will use traditional, FDA-approved masks. The use of blue masks by team members who don’t directly care for patients will help keep inventory up of FDA-approved masks for those team members who provide direct patient care.

“People love these blue masks,” Barkel said. “It’s a really effective mask. It’s extremely good at filtering the aerosol of the virus and it saves a bunch of really hard-to-get inventory. It’s tough to get masks these days.”

Barkel said he’s impressed with the collaboration.

“A lot of these companies are looking for ways to help,” he said. “A lot of them have sewing operations and people skilled at sewing. It’s really important to have good quality control on this. You want to make sure they’re all made exactly the same.”

Cory Clolinger, Spectrum Health value analysis program specialist, said he appreciates how manufacturers retooled and innovated to help during this time of need.

“This has been a huge help in bridging the gap,” Clolinger said. “This support, along with all of the donations we have received from our community, have allowed us to better prepare for taking care of COVID-19 patients.”

Many of the manufacturers considered the project to be a win-win. During uncertain times, it’s helped keep people working.

Genesis Seating

Kevin Kuske, private label president for Genesis Seating in Kentwood, said his team is grateful for Spectrum Health.

“We wanted to help out,” he said. “Everyone here is so grateful for what the frontline health care, fire, police, store employees … are doing to take care of our communities. It is the least we can do to help in return. We are fortunate to have some amazingly talented sewers and upholstery designers working with us. It is a little secret that we have this amazing talent in West Michigan that rivals the best in the world.”

Kuske said employees jumped in enthusiastically, with sewing machines whirring.

“The response has been very positive,” Kuske said. “We really feel like we can help. This is such a crazy time and it is easy to feel helpless and that things are out of your control. This gives us both a way to help and a way to feel a bit of control. All of us have family and friends who are out there risking their health to keep our communities safe, so this is also personal.”

Fomcore

Kelsey Oetman, human resources coordinator at Muskegon-based Fomcore, said her team also felt thrilled to be helping.

“This virus has showed us all that the community we are a part of is an extension of our Fomcore family,” she said. “Being able to bring folks back to work, to mass produce something so desperately needed right here in our area, makes us all feel like we’re part of something really important. We have the capacity to produce tens-of-thousands of masks, so we wouldn’t be the company we say we are if we didn’t step up to that challenge.”

Joyce Osterberg, a Fomcore industrial sewer, gladly stepped in to help Spectrum Health.

“I’m happy we get to come to work and help our country stay safe by making these masks and help to win this invisible war,” Osterberg said.

Chad Bitson, a Fomcore table operator, said he’s happy to be back to work.

“We were excited to help wherever we could,” he said. “The cherry on top was bringing the Fomcore family back together and witnessing the teamwork that allowed us to immediately make thousands of masks a day.”

American Seating

Kevin Koehler, vice president of manufacturing for American Seating in Grand Rapids, said his company has helped in crises since the days of World War II. American Seating is giving bonus compensation to employees working on masks.

“It’s a way to show our gratitude for their willingness to come into the factory and do this good work during this crisis,” Koehler said.

“With the COVID-19 pandemic, we’re glad to help our community as much as we can. A number of our employees have been itching to get back to work. When people heard that the masks were needed by Spectrum Health—that they would be helping health care providers right here in our community—they felt this is an important thing to do.”

/a>

/a>

/a>

/a>

/a>

/a>